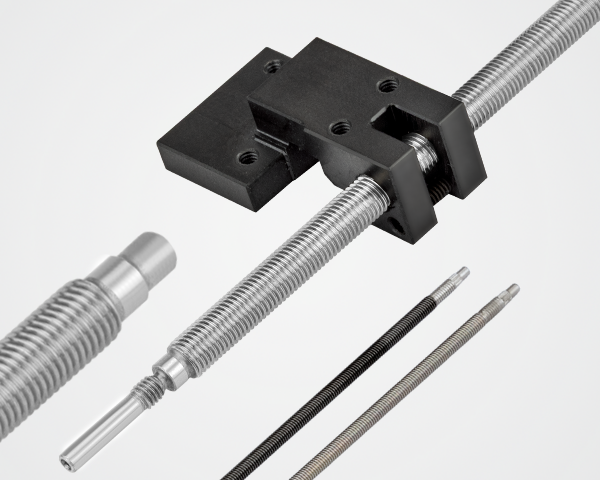

Lead screws and Lead Screw Drives

Ultra-fine threads · rolled / ground · special geometries · special materials · all coatings & lubricants

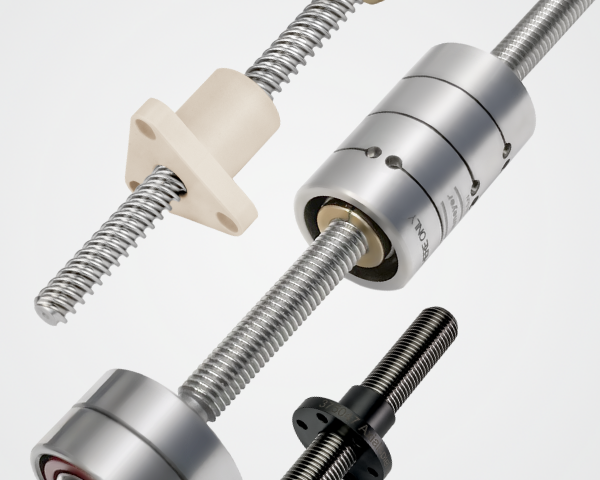

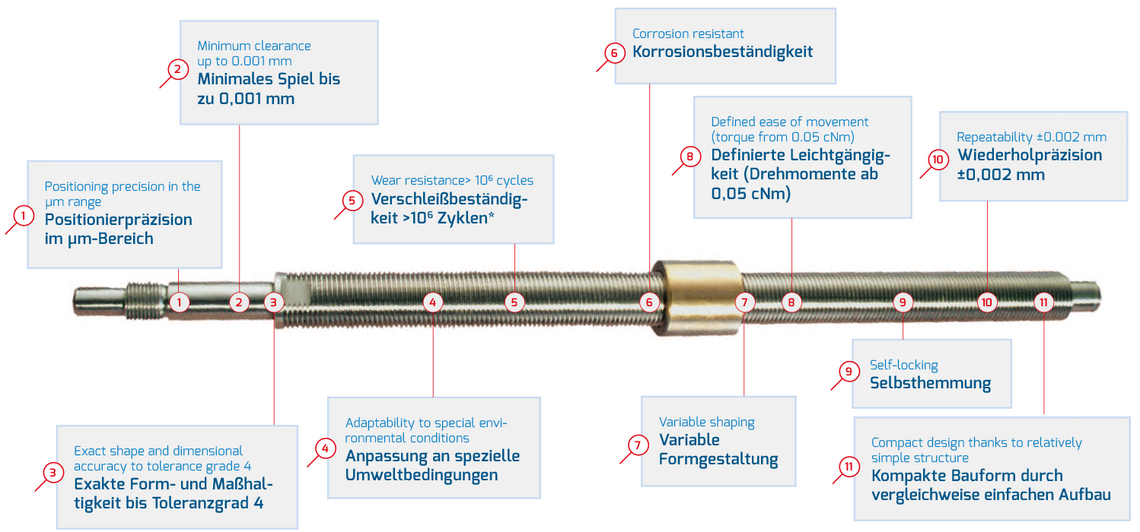

Ultra-fine precision when standard solutions are not sufficient: Feinmess Suhl develops and manufactures high-accuracy precision lead screw drives with ultra-fine, ground or rolled threads for applications with the highest requirements in terms of accuracy, stability, and repeatability. More than 140 years of experience, combined with proven and modern manufacturing technologies, enable micron-level accuracy, custom geometries, and flexible solutions — from single components to small batch production.

A key focus lies in application-specific customization. Multi-start designs, special leads, functional coatings, or exceptional thread geometries are precisely tailored to the respective application. Feinmess Suhl deliberately remains flexible in production volumes, offering both single parts and small series without compromising quality, stability, or service life.

The result is precision lead screw drives designed for applications where standard solutions reach their limits — durable, highly accurate, and engineered down to the smallest detail.

-

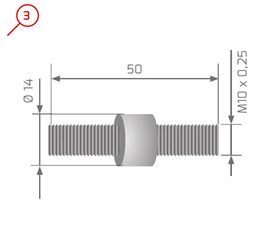

Ground Threaded

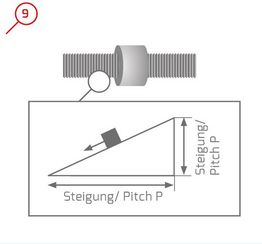

Lead Screws- Leads: from 0.2 mm, lead angles up to 40°

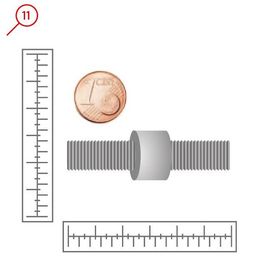

- Diameter: 2 – 25 mm

- Length: up to 300 mm

- Full range of material combinations

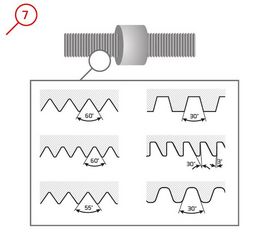

- Thread forms: metric, Whitworth, trapezoidal, buttress, special forms

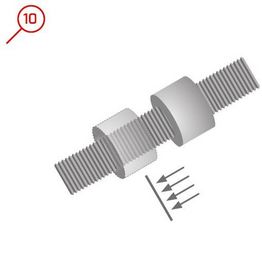

- Single-start and multi-start designs

- Optional: lubrication, coatings, tribology, assembly development

-

Rolled

Lead Screws- Leads: from 0.2 mm, lead angles up to 90°

- Diameter: 3 – 25 mm

- Length: up to 3 m

- All material combinations available

- Thread forms: metric, UTS, Whitworth, trapezoidal, custom forms

- Single-start and multi-start

- Optional: lubrication, coating, tribology, assembly development

-

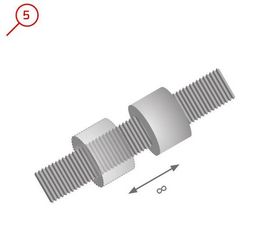

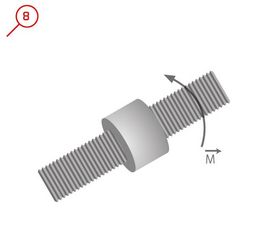

Nuts for

Lead Screws- Nut design: cylindrical, flanged, anti-backlash

- Materials: brass, bronze, steel, plastic, PEEK, and others on request

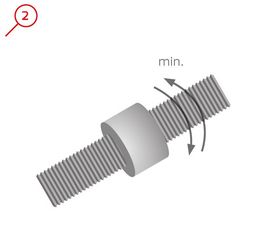

- Various preload options, defined backlash, fitted / paired nuts

- Customer-specific special geometries

- Optional: functional coatings, special solutions, additional functions, integration and assembly development

-

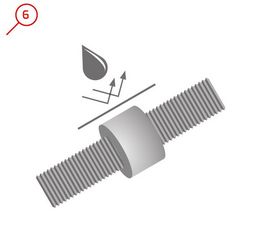

Coatings

- Corrosion-protective coatings

- Surface-hardening coatings

- Plastic coatings

- Friction-reducing e.g. Diconite, PVD, DLC

-

Lubricants

- Cost-optimized lubrication

- Permanent lubrication

- Low-friction greases

- High-temperature and low-temperature lubrication

- Cleanroom & vacuum lubrication

- Medical, pharmaceutical, and food-grade lubricants

- Customer-specific special lubrication e.g. aerospace

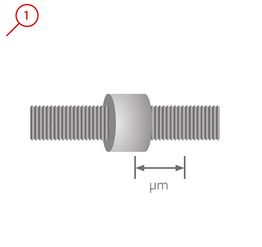

in the µm range.

High-precision manufactured threaded spindles and nuts are fitted and lapped by hand at Feinmess Suhl until perfect ease of movement