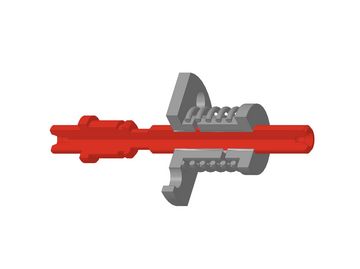

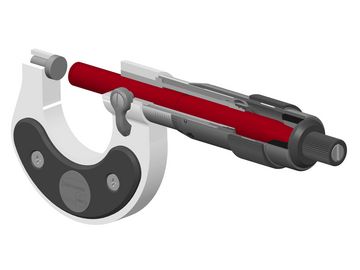

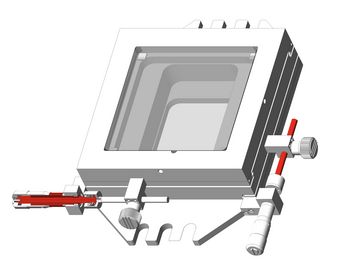

Components for positioning, micrometer heads, positioning systems, metrology and calibration technology

Product Overview

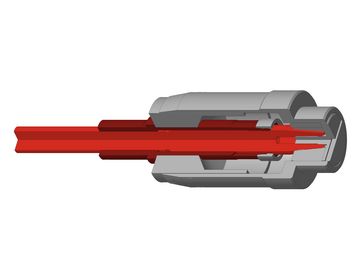

The grinding of high-precision threaded spindles has been the core competence of Feinmess Suhl from the beginning. 140 years of experience combined with modern and proven technology are the guarantors for highest quality and precision in the µm range. Negative influences of temperature fluctuations or impurities on the grinding process and thus the quality of the ground spindles are excluded by air conditioning of the production rooms and filtering as well as additional cooling of the high-purity grinding oil.