Micrometer stages / positioning systems

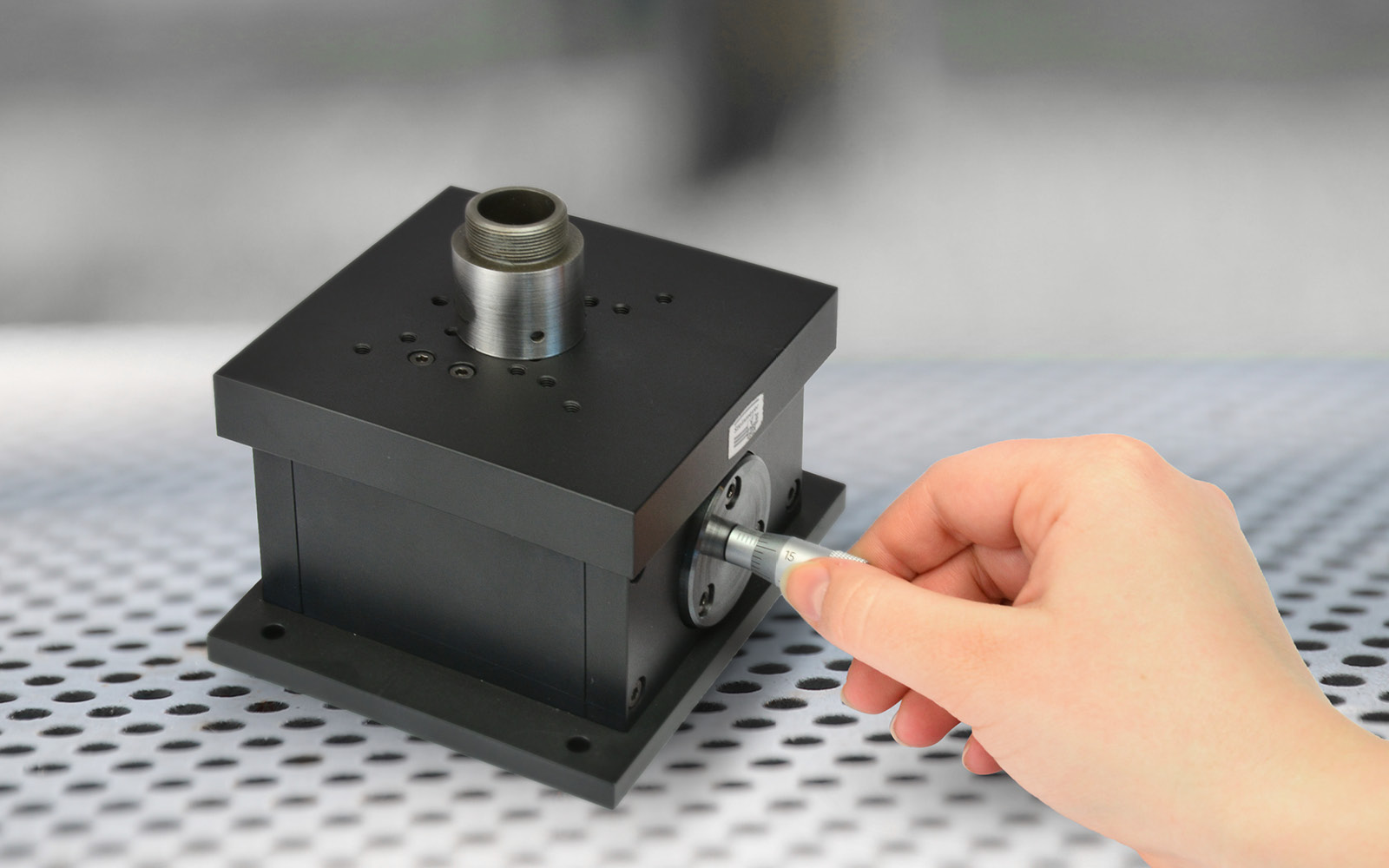

Positioning systems are created by combining threaded spindle, micrometer heads and other components such as high-precision linear guides. The threaded spindle is also used here as a solid measure for the movement in the individual axes. The positioning assemblies are used for high-precision coordinate-controlled positioning of workpieces, dies and other elements in multiple axes. To ensure the perfect operation of the overall system, the individual components are manufactured with the highest precision, fitted by hand and then subjected to a final quality check.

For the adjustment to different environmental conditions and requirements, Feinmess Suhl demonstrates flexibility and efficiency by developing specifically sized positioning systems as per client requirements. These are as varied and diverse as their applications. Thus, the following shows standard versions which can be modified to suit the requirements.

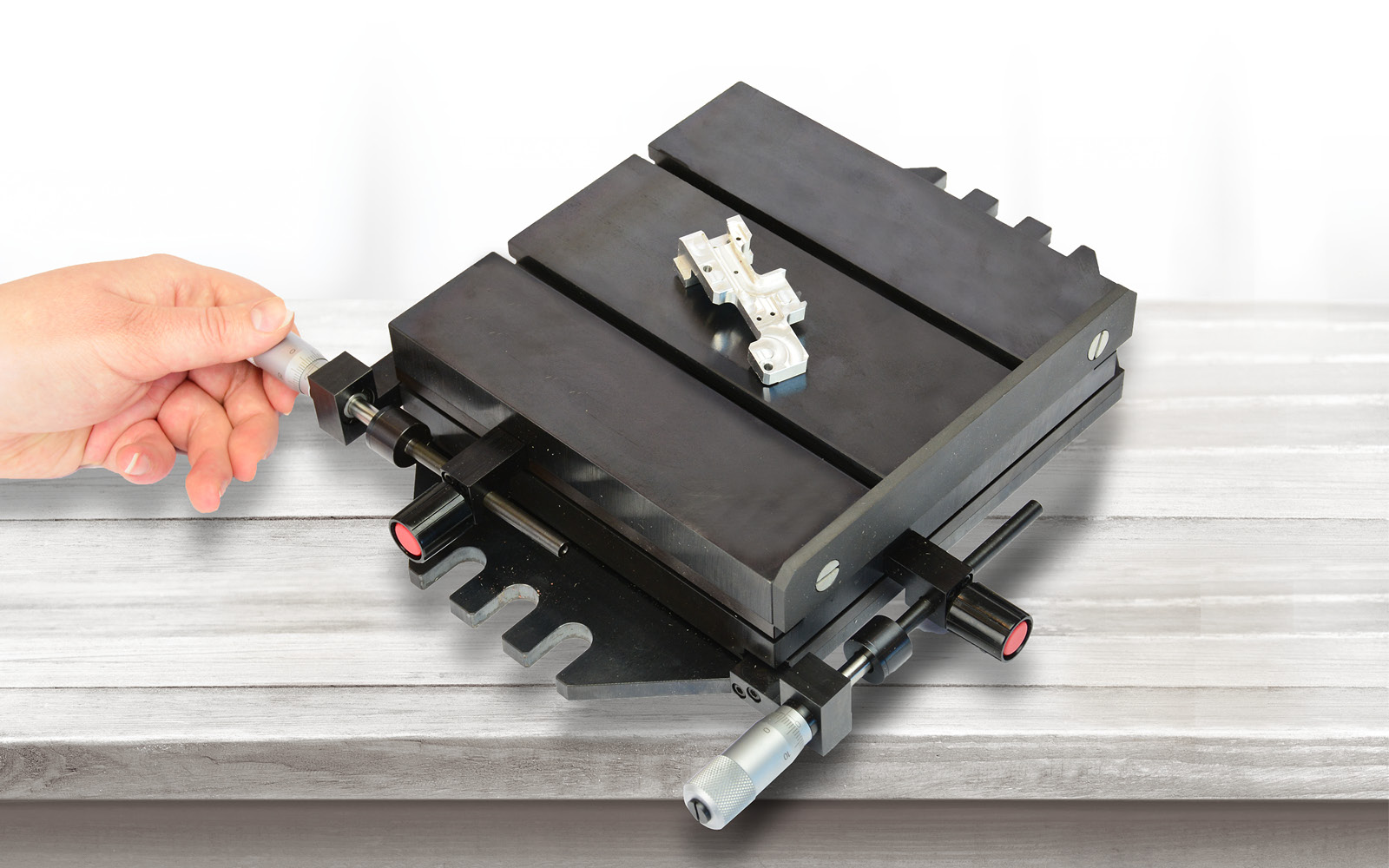

Linear adjuster LT

Micrometer stage with Travels 5 - 50 mm, Repeatability 2 µm, Load 1.5 - 5 kg, Resolution micrometer screw 10 µm