Lead screws and lead screw drives

Grinding high-precision lead screws has been the core competence of Feinmess Suhl from the company's beginning. 140 years of experience combined with modern and proven technology are the guarantors for highest quality and precision in the µm range. We offer flexibility and performance in the development and production of specific solutions for your customers - even for small quantities.

Product Portfolio

Individual development & production from batch size 1 to large series

Customized lead screw drives

Individually customized: Material + nut + thread type + cleaning + environmental conditions

+ more ...

Branch specific lead screw drives

Individually customized: Semiconductor Technology + Aerospace + Microelectronics + Vacuum

Large series lead screw drives

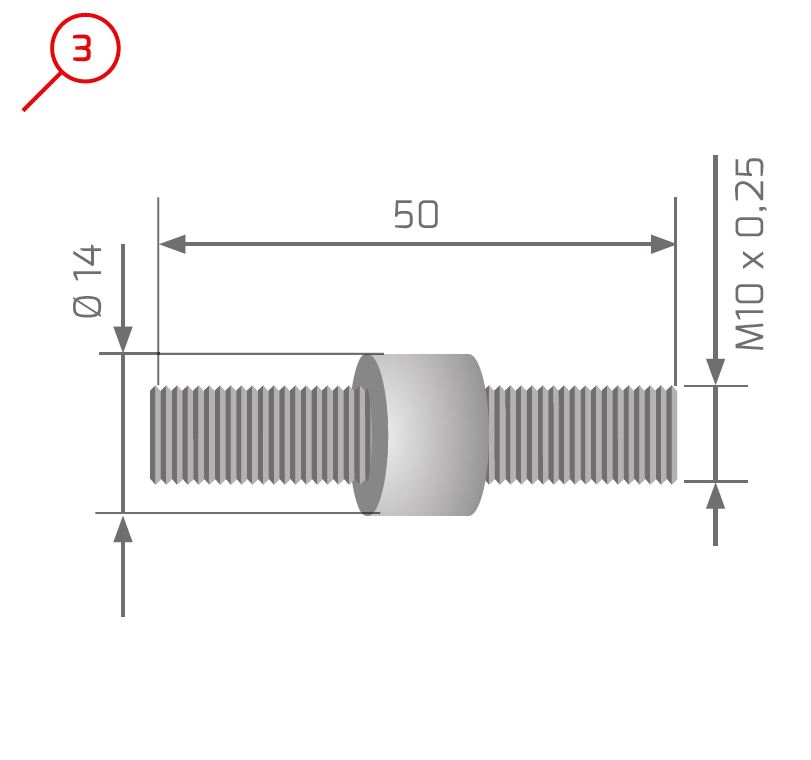

screw + nut + pitch 0.25 - 7 mm + length up to 500 mm + stroke 50 - 230 mm + axial play <=0.02 mm

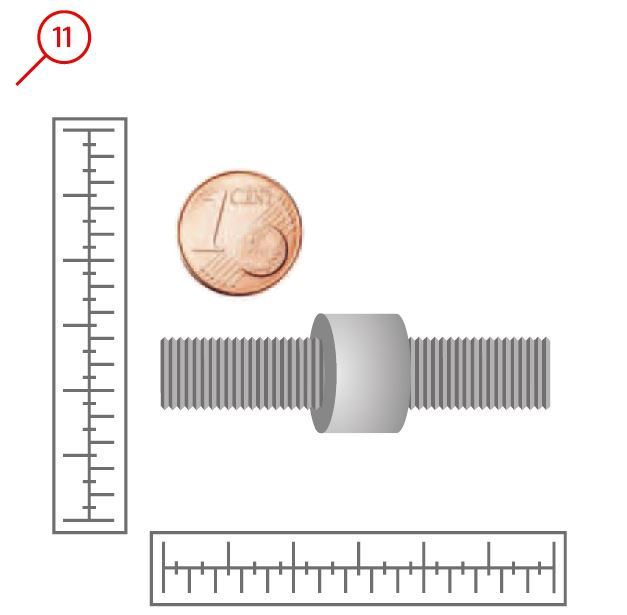

Technical components - in detailed precision

Your configuration options

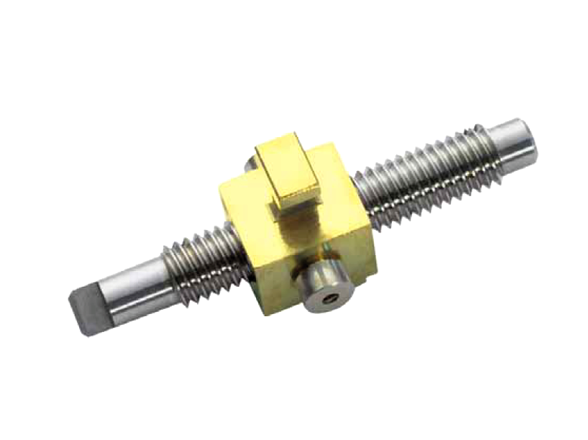

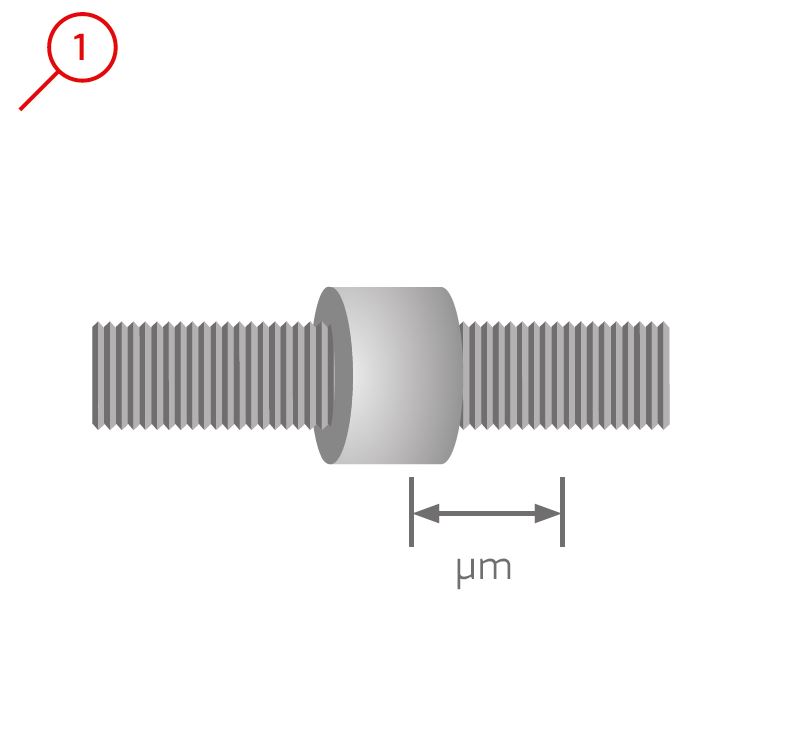

Positioning precision in the ?m range

High-precision manufacturing and assembly are the guarantee for Feinmess Suhl‘s high quality of work, which achieves a positioning accuracy of the finished assemblies

in the ?m range.

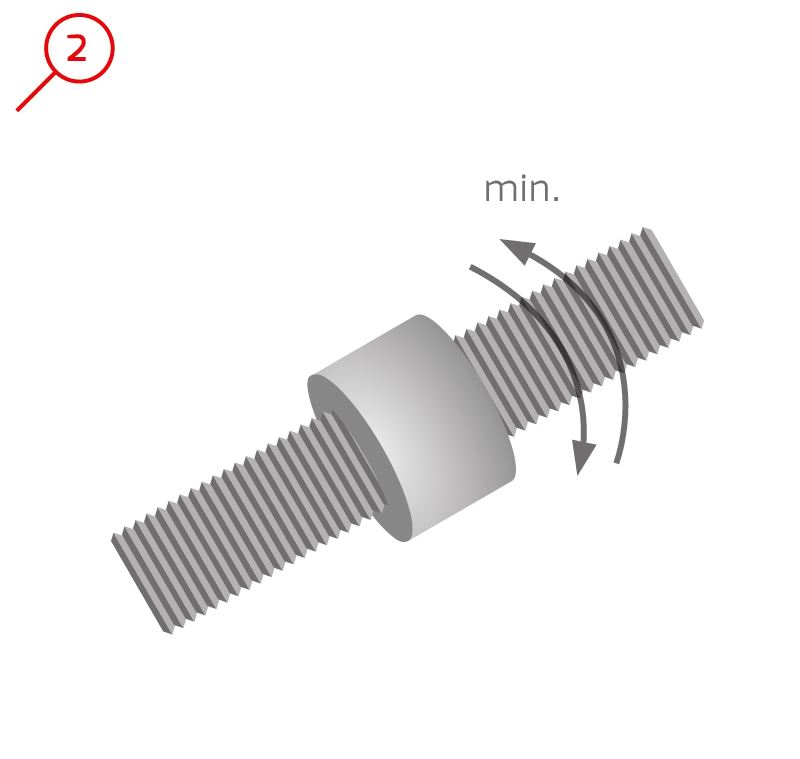

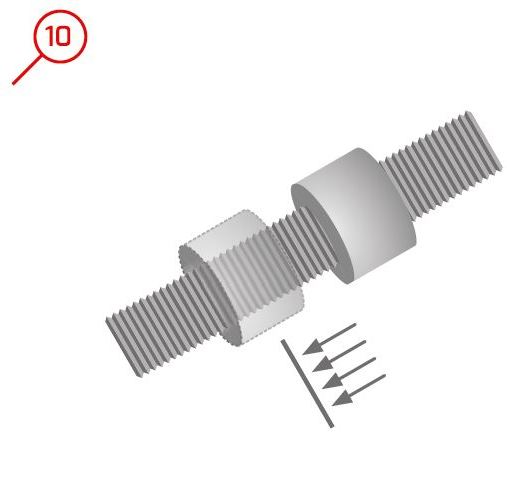

Minimum clearance up to 0.001 mm

High-precision manufactured threaded spindles and nuts are fitted and lapped by hand at Feinmess Suhl until perfect ease of movement and at the same time minimum clearance is achieved.

Exact shape and dimensional accuracy

Developed by skilled designers and manufactured by experienced specialists, the threaded spindles by Feinmess Suhl meet minimal tolerance specifications in line with the highest industry standards.

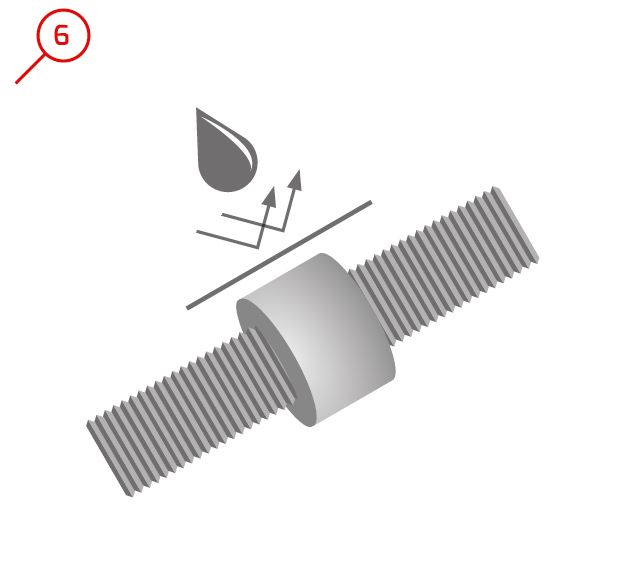

Wear resistance > 10E-6 cycles

Feinmess Suhl‘s threaded spindles are particularly wearresistant and durable for their respective application thanks to the selection of ideal material combinations, lubricants and coatings.

Corrosion resistance

If necessary, corrosion resistant materials are selected for the threaded spindles for the relevant application conditions in order to ensure a long life.

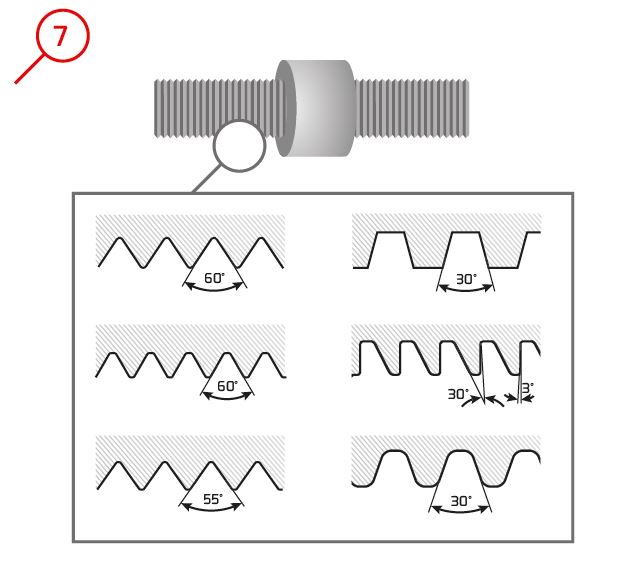

Variable formgestaltung

Specialist designers perfectly dimension the adjusted threaded spindles to the individual client requirements with regards to material, thread form and other technical parameters.

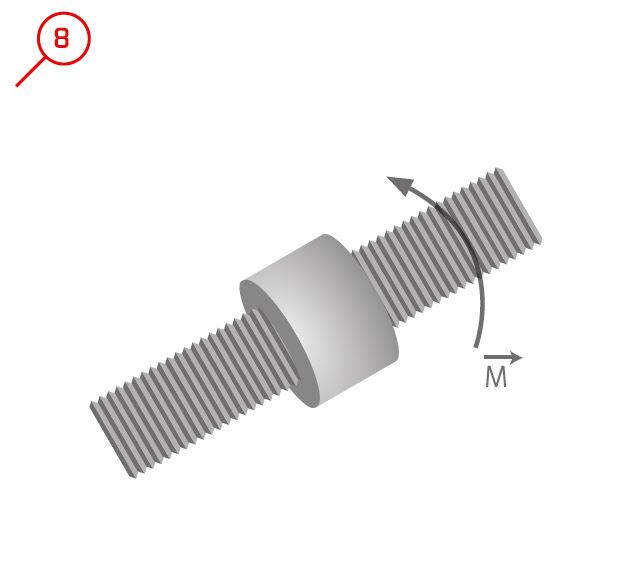

Defined ease of movement

(torques from 0.05 cNm)

High-precision manufactured threaded spindles and nuts are fitted and lapped by hand at Feinmess Suhl until perfect ease of movement

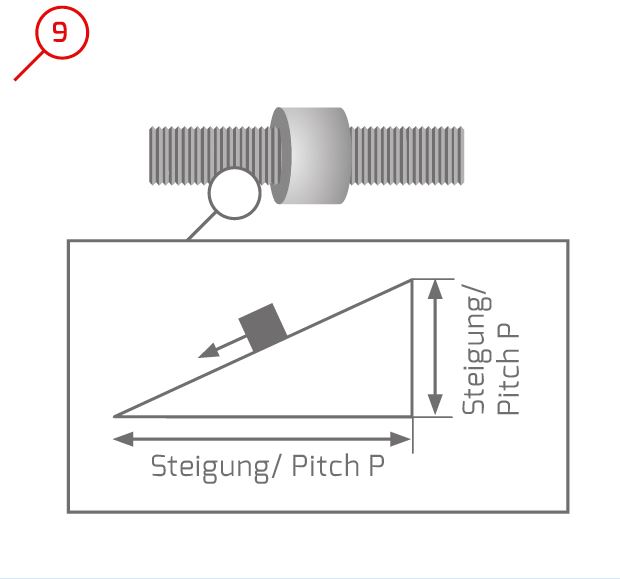

Self-locking

Depending on the friction occurring for metric threads, these can be designed as self-locking. In this case, the nut position on the spindle is held by static friction, and a separate locking component is not necessary.

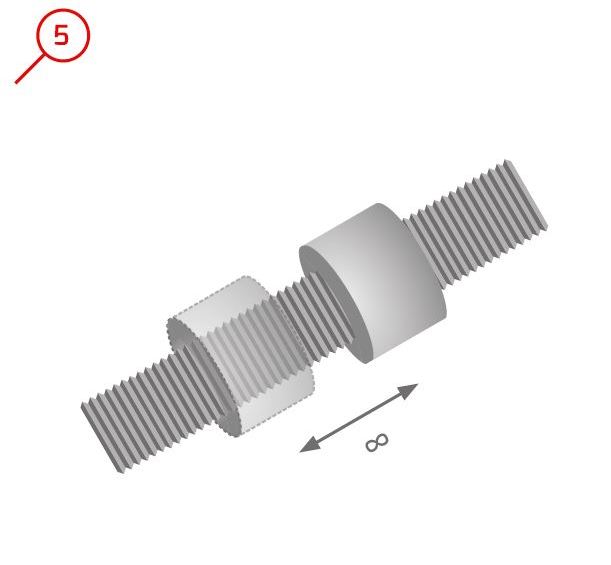

Repeatability ± 0.002 mm

High-precision manufacturing, minimal clearance and exact shape and dimensional accuracy guarantee a high repeatability of ±0.002 mm during positioning.

Compact design

Depending on its simple configuration of only two components, the screw drive only takes up little space in an assembly. Thus the positioning modules by Feinmess Suhl are likewise relatively compact.

Request a quote

Let us know your exact requirements and we will contact you as soon as possible: