Systems for monitoring of test equipment

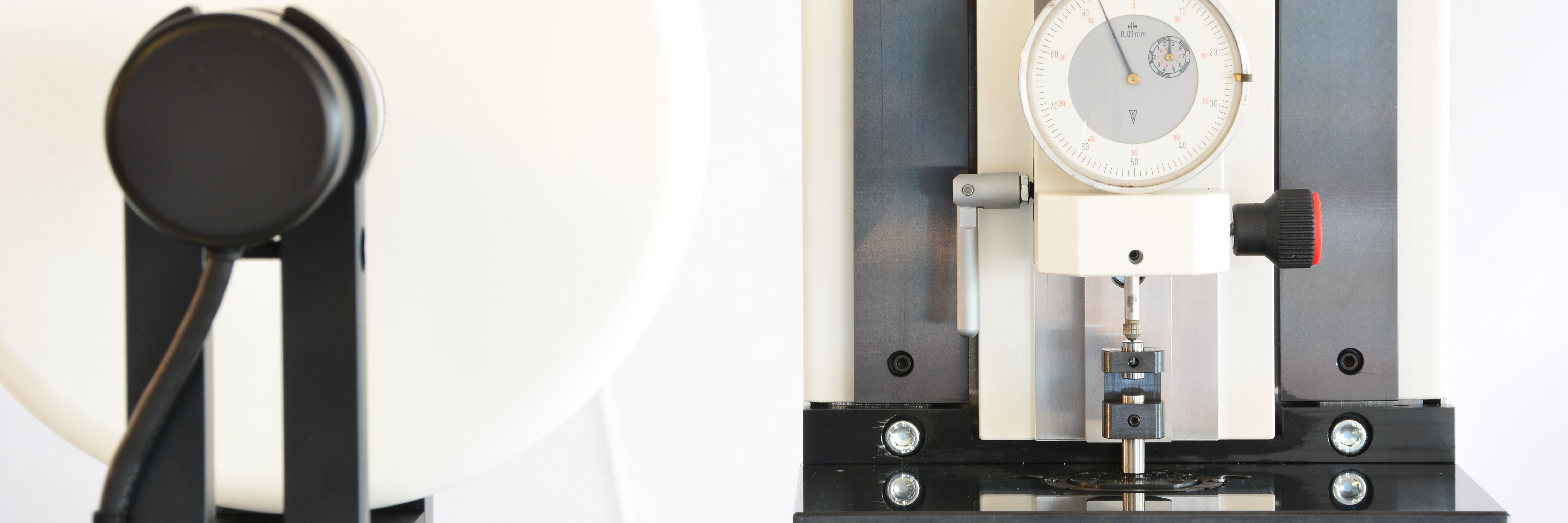

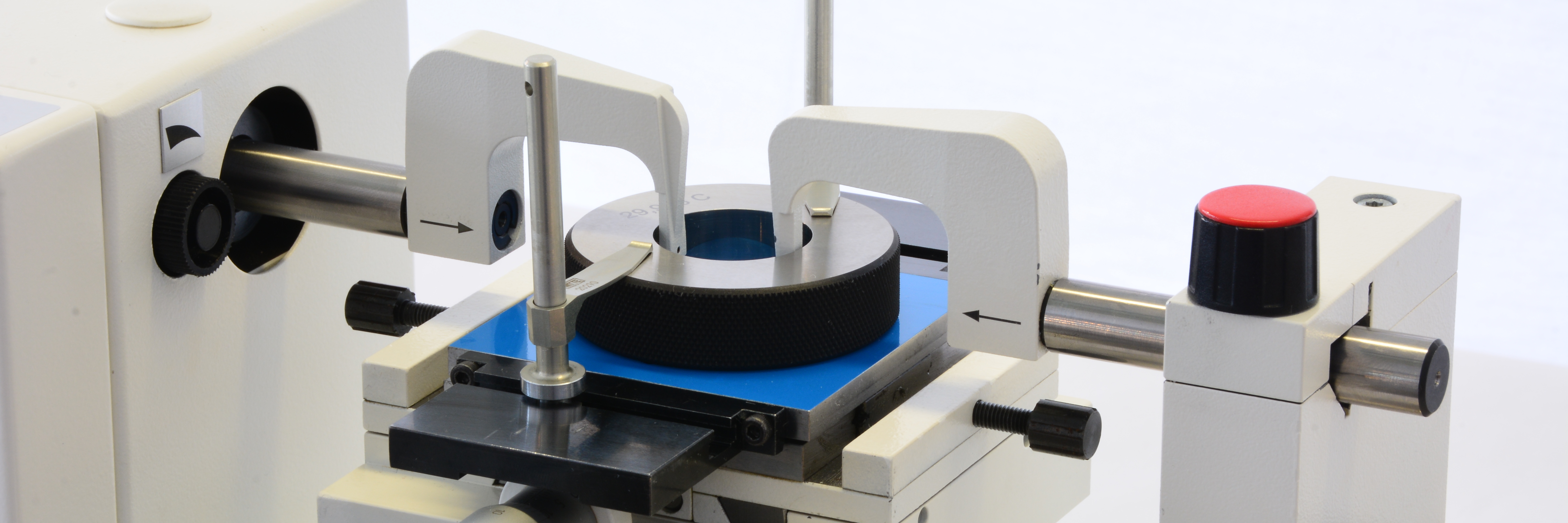

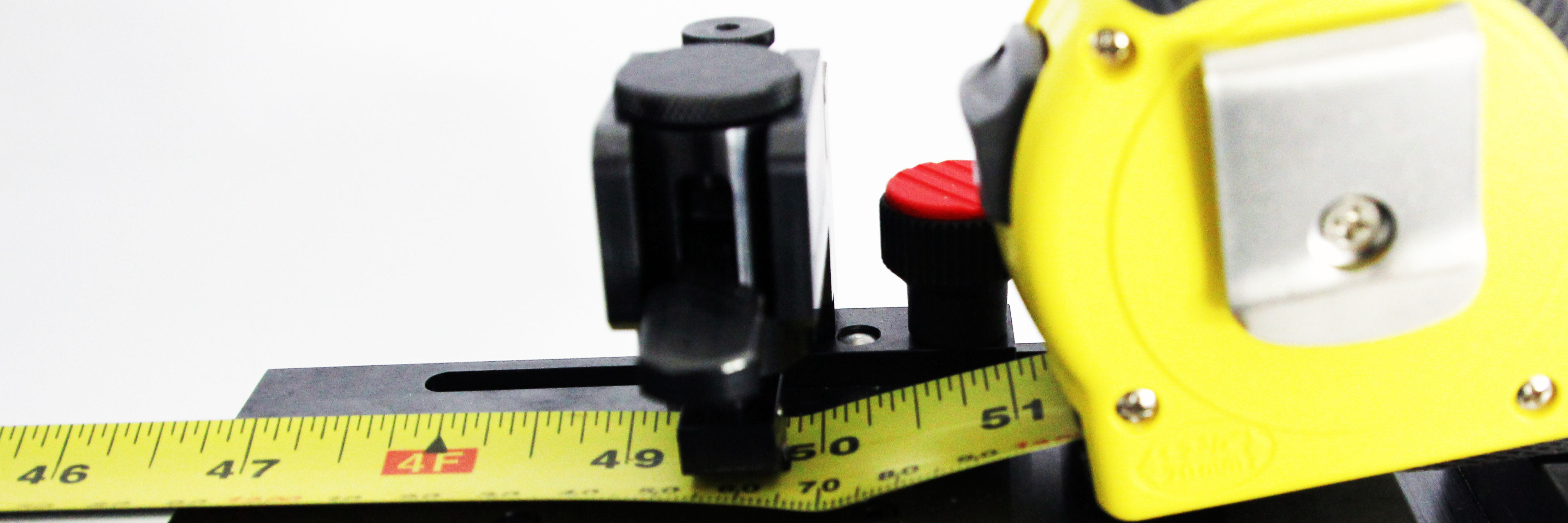

Greatest accuracy of test equipment is one of the most important tools within the manufacturing process for component manufacturing. Depending on the workpiece, a range of precision measuring instruments is used during and after production.

This test equipment requires regular monitoring in order to avoid measuring inaccuracies due to wear and to maintain consistent measuring results. During this process, it has to be ensured that the test equipment complies with the relevant factory standards or national/ international standards. Consistent test equipment monitoring helps to avoid faulty productions and resulting follow-up costs.

Systems for test equipment monitoring by Feinmess Suhl meet the sophisticated requirements with regards to cost efficiency and quality management integration. We support in-house QM departments as well as independent test labs with regards to all tasks of efficient and reliable test equipment monitoring according to the applicable norms and QM systems using suitable measuring technology and software systems. In addition, we develop - as required by our clients - individual solutions which include specific technical features and needs.